Old Sheffield Plate

In 1743, Thomas Boulsolver of Sheffield, England, discovered that he could bind a sheet of Sterling silver to a copper ingot by pressing and rolling the two metals into a workable sheet. The friction from the process caused enough heat to fuse the metals to each other.

This sheet could then be made into a teapot, a tray, or other household object. During the late 1760s, the silver was fused to both sides of the copper, making a kind of “silver sandwich.” Silver pieces consisting of this sandwiched metal eventually became known as Old Sheffield plate.

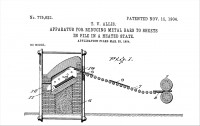

The image below shows a 1904 patent for reducing metal bars to sheet. As heated metal is forced into the rolling mill, the rollers compress, squeezing the metal to the desired thickness. In practice, the ingot is reduced through a series of rolling stands, each one making the metal a little thinner than the previous rolling stand (All images will enlarge if selected.)

Even though other countries produced Sheffield plate in the 18th century, the English excelled at making Sheffield plate and received over 90% of the orders for it. Therefore, much of the remaining Sheffield plate will be English.

Identifying Old Sheffield Plate

The undersides of Old Sheffield plate were tinned rather than silverplated. This means that areas like the underside of a sugar bowl cover or the undersides of candlesticks were covered with tin, not silver. Tinning is done by coating the under-surface with molten tin, and that surface has a slightly rougher look than sheet.

Many pieces of Old Sheffield plate, such as urns and coffeepots, were formed by taking a piece of sheet and rolling it into a cylinder. The cylinder has a seam. Originally, this seam was burnished to hide the seam. After years of polishing, the seam becomes visible. If you breathe on the area, forming a frost, the seam can show up as an orange cast of the copper at the seam line. The presence of an orange seam line, all other things being equal, is proof that the item is Old Sheffield plate.

Since Sheffield plate is a “silver sandwich,” the exposed edges have to be rolled over or covered with silver wire or thread (called a wrapped edge) to prevent people from seeing the copper layer in the middle. Look for rolled edges, too.

Sometimes an area like the rim of a teapot or coffeepot, on which the lid rests, is not rolled. If you can angle it so you can look at the edge with your loupe, you will be able to see the metal layers with the copper in the middle.

If your piece has a coat of arms engraved on the surface, try breathing around the edges. Sheffield plate manufacturers inserted silver sections so the engraving would not cut through to the orange, copper layer. The air will condense around the outline, giving you an indication that the piece is not solid silver.

The image below is a Sheffield plate argyle. Argyles were doubled-walled pots used to keep gravy warm as they were carried from 18th century kitchens (often detached from the main house) to the dinning room. Note the chamber in the handle where hot water was poured.

(This article is an excerpt from All About Antique Silver with International Hallmarks, by Diana Sanders Cinamon. Copies of the book can be purchased through the on-line store.)